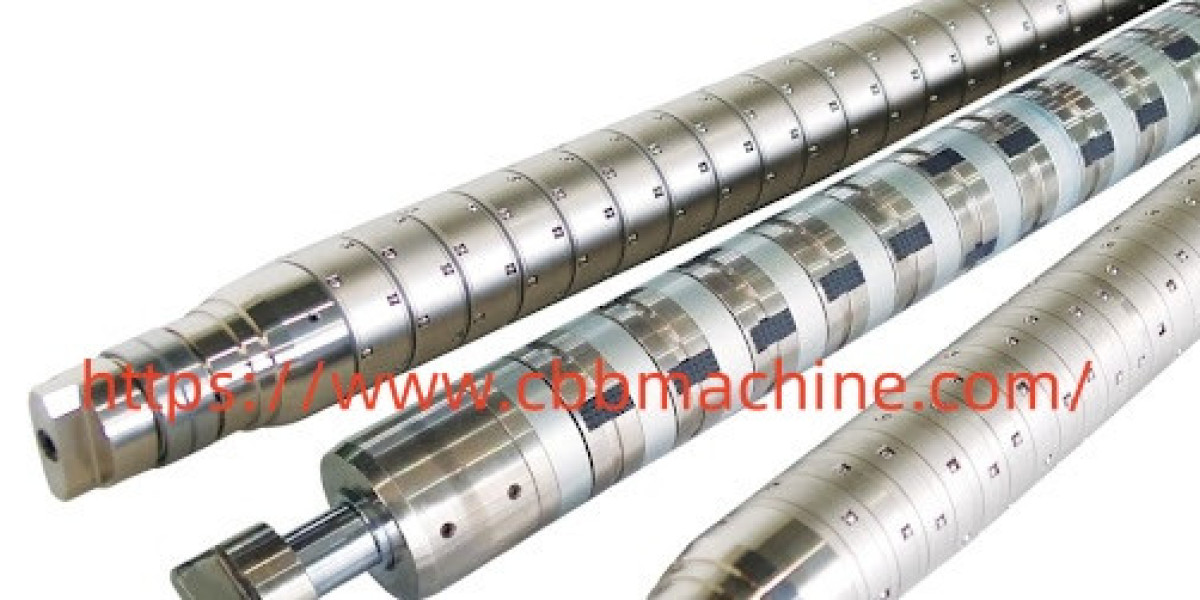

In modern web handling and roll-to-roll production systems, the Differential Air Shaft plays a vital role in ensuring uniform material winding and smooth operation across various industrial applications. Designed to balance tension across multiple rolls, this component allows for simultaneous winding of different widths, making it essential in processes involving paper, film, foil, or textile materials. Its precise control improves efficiency, reduces waste, and maintains consistent product quality throughout production.

The primary advantage of this expanding shaft lies in its ability to distribute torque evenly. By using compressed air to secure roll cores, the system maintains stable rotational motion even when dealing with materials of varying diameters or thicknesses. This mechanism helps prevent slippage, uneven winding, or roll deformation, which are common issues in high-speed production environments. Such precision is crucial for industries where material integrity directly impacts product performance and downstream processing.

Manufacturers benefit from its adaptability. The air-driven roll system can accommodate multiple rolls on a single axis, providing simultaneous tension control and reducing line stoppages. This design flexibility allows operators to handle different material widths without the need for extensive machine adjustments, saving time and enhancing productivity. It also supports both automatic and semi-automatic production lines, integrating seamlessly with modern industrial setups.

Durability and reliability are key considerations in its design. High-quality steel or aluminum components, precision machining, and balanced construction ensure long-term operational stability. The air expansion mechanism is carefully engineered to maintain consistent gripping force while minimizing wear on both the shaft and the roll cores. Proper maintenance is straightforward, allowing quick inspection and servicing to keep production lines running efficiently.

In addition to performance, safety is another critical factor. The secure gripping system minimizes the risk of roll slippage or sudden release, protecting both operators and machinery. Its simple engagement and disengagement process reduces human error and allows faster roll changes, which is especially important in high-volume or continuous operations.

Technological integration has further enhanced the functionality of these shafts. Modern systems can incorporate sensors and control units to monitor tension, adjust air pressure automatically, and communicate with broader automation setups. This capability supports data-driven production optimization and predictive maintenance, aligning with the growing trend of smart manufacturing.

Selecting the right system involves assessing factors such as roll weight, material type, line speed, and production complexity. Working with a trusted supplier ensures that the expanding shaft meets all operational requirements while providing reliable performance under diverse conditions. This combination of precision, flexibility, and durability makes it an indispensable component in many industrial lines.

Overall, air-driven winding systems exemplify how innovation in mechanical engineering can optimize production efficiency, enhance safety, and improve material handling accuracy across multiple industries.